pias® drilling screw, hexagon head with long drill tip

pias steel zinc-plated with long drill tip

SCR-DBITL-WS8-(A3K)-5,5X32

ZEBRA PIAS

Register now and access more than 15,000 products

Reduction of the assembly time by the drill tip by min. 50%:

- Drilling without graining

- Thread moulding

- Securing

all in one operation

Suitable for component combinations t I / t II according to approval ETA-10/0184

- Steel / steel

And additionally for the fixing of latches on steel substructures (bolt connections)

- Drilling screws must be processed with a suitable drill driver (e.g. cordless drill driver with depth stop)

- The use of impact screwdrivers is not permitted

- Drilling screws must be attached perpendicular to the surface of the component

Galvanized drilling screws may only be used where dampness is not to be expected. For fasteners with a construction permit, the permit, and in particular Part 2 "Special regulations", must always be observed.

| |

Standards | CS |

Material | Steel |

Surface | Zinc plated |

RoHS-compliant | Yes |

Head type | Hexagon head |

Drive type | Hexagon |

Thread type | UNC |

Shape of tip | Drilling tip |

Underground | Steel, Aluminum |

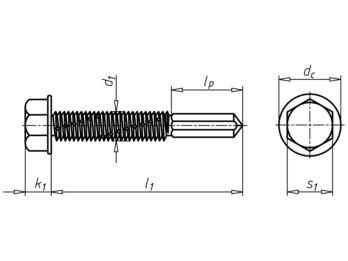

Nominal diameter (d1) | 5.5 mm |

Length (l1) | 32 mm |

Head diameter (dk) | 10.9 mm |

Head height (k1) | 5.15 mm |

Drill tip length (lp) | 14.0 mm |

Screw-thread length with drill tip | 29.0 mm |

External drive (s1) | WS8 |

Max. material thickness to be drilled through (metal) | 13.5 mm |

For max. substructure thickness | 12.0 mm |

Min. recommended substructure thickness | 2 mm |

Min./max. attachment thickness | 2.0-15.0 mm |

Approval | ETA-10/0184 |

Min./max. recommended installation speed (idling) | 1200-1800 rpm |

Datasheets (1)

CAD data (available after login)

Certificates/ Documents (0)