For detailed information, other images and documents, please select individual articles from the following table.

Flap disc with ventilation holes ZEBRA SPEED

Flap disc with M14 connection, nylon backing plate and cooling holes for heat dissipation

Register now and access more than 15,000 products

Variants

Register now and access more than 15,000 products

Call customer service: +44 03300 555 444

Prices for customers after login

Nylon backing plate with ventilation holes offering various advantages:

- The ridges inside the backing plate cavity combined with the external holes let the air circulate cooling the metal during the sanding operation. This prevents the phenomenon of stainless steel turning purple

- The circulating air also cools the abrasive cloth, which reduces deterioration of the resin gluing the sanding grits. This means that the grits do not separate from the cloth, lengthening its service life

- The backing plate has a central thread (M14) which makes it quicker and easier to fasten the disc to the grinder

Disc with a core with more smaller flaps, enabling even and complete disc wear

Despite a narrower core, the disc holds around 25% more abrasive cloth than a traditional disc

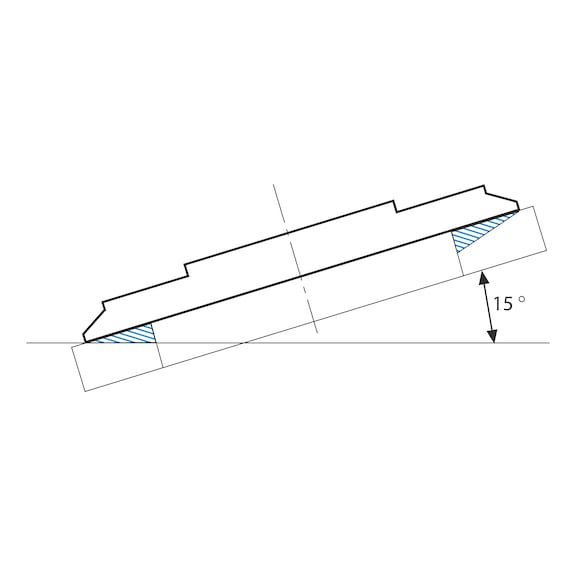

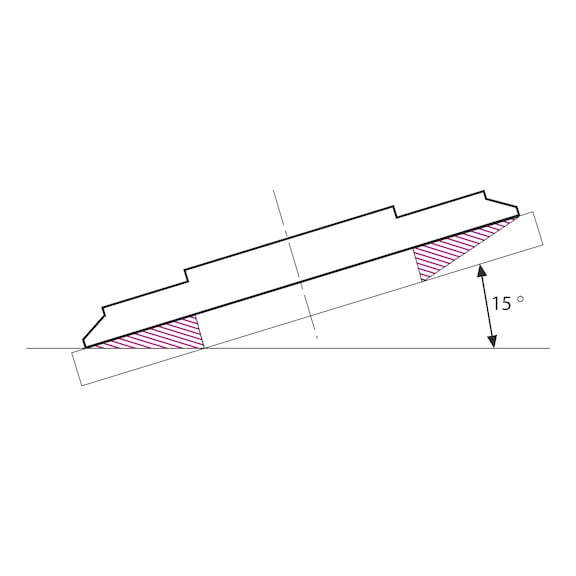

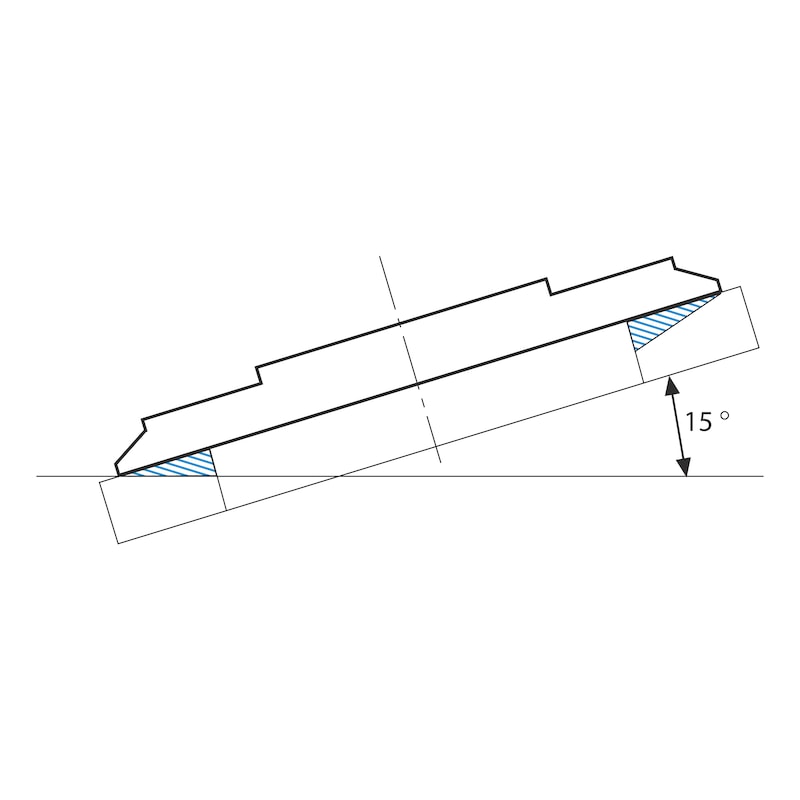

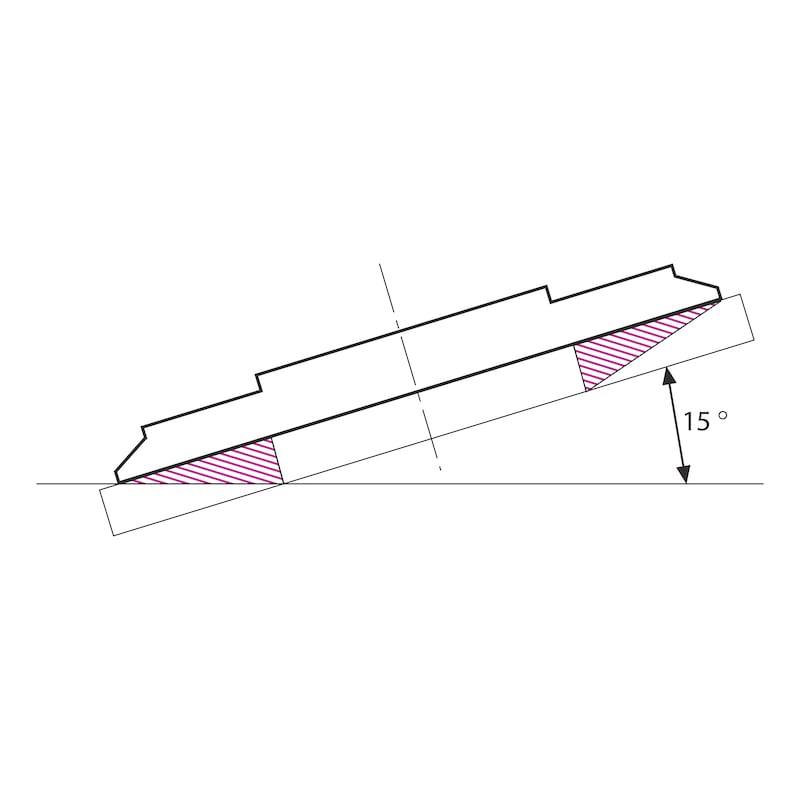

Thanks to the special angled shape of the flaps, the abrasive cloth is dressed very quickly, preventing the disc from going blunt, thus enabling more precise processing on the sanding area

Disc with very high performance and heavy-duty resistance

To obtain maximum disc performance, use a grinder with minimum output of 1000 W

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!